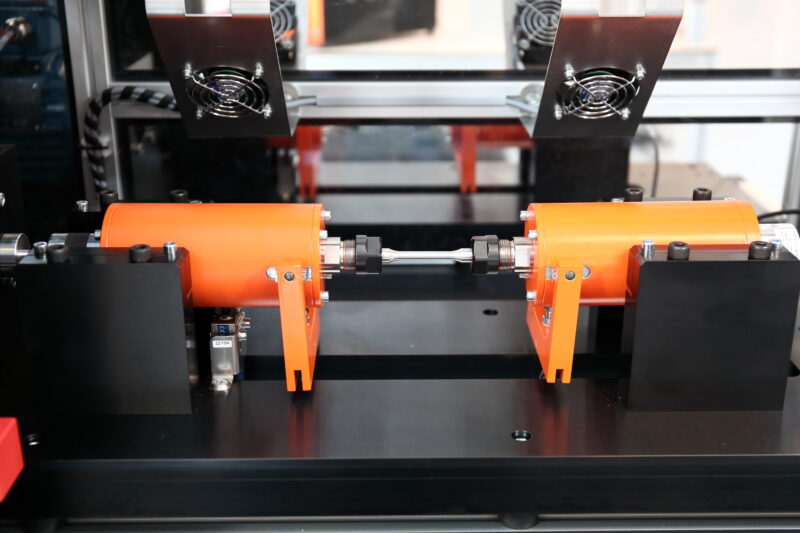

RR Moore Fatigue testing system

Rotating Beam - ISO1143

Rotating Beam - ISO1143

The RR Moore Fatigue Testing Systems’ design is based on the rotating beam principle. The specimen functions as a simple beam symmetrically loaded at two points. When rotated one half revolution, the stresses in the material originally below the neutral axis are reversed from tension to compression and vice versa. Upon completing the revolution, the stresses are again reversed so that during one revolution the test specimen passes through a complete cycle of flexural stress (tension and compression).

Specimen loading

The RR Moore Fatigue Testing System can be equipped to test straight shank specimens. The standard specimen length is appr. 90 mm. Specimens 25 mm longer or 25 mm shorter can be tested without affecting the calibration of the system.

Straight shank specimens are held in place using precision specimen collets.

Stress is applied to the specimen by direct application of dead- weights to ensure precise loading.

Controller including cycle counter

Integrated variable speed control provides the RR Moore Fatigue Testing Systems’ capability to operate at speeds from 500 RPM to 10.000 RPM. Speed control is important in testing certain materials that heat up when highly stressed, and it allows certain correlations of results between high speed tests and lower speed test.

Controller is provided with a touchpanel display showing: