Specimen preparation

Compact and easy-to-use Milling Machine

Compact and easy-to-use Milling Machine

Compact and easy-to-use Milling machine.

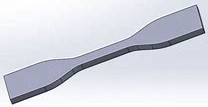

Especially fit for preparing specimen in “dogbone” shape, or any other shape, for tensile tests or other material tests.

Frame is built from a welded steel structure. With a fixed gantry and a mobile table in Y, to create a robust Milling machine. Spindle 800 W, for rotational speed from 8.000 to 24.000 rpm. Max milling tool diameter 8mm.

2D Software

2D CAD module, 2,5 axis CAM module for toolpath processing and driving module for Milling Machine. Accepts .ISO and .PCB format.

Electronic

CN3 microstep digital control; 3 interpolated electronic axes. Communication RS232.

Steppermotors, microstep management; resolution 0,003mm. Maximum speed 100 mm/s.

Ball type linear guides and ballscrew spindles for X,Y,Z movements.

Safety

Integral transparent cover with 180° free sight. Safety Cover is locked during operation. Compliant with CE Machine Directive regulations.

Options