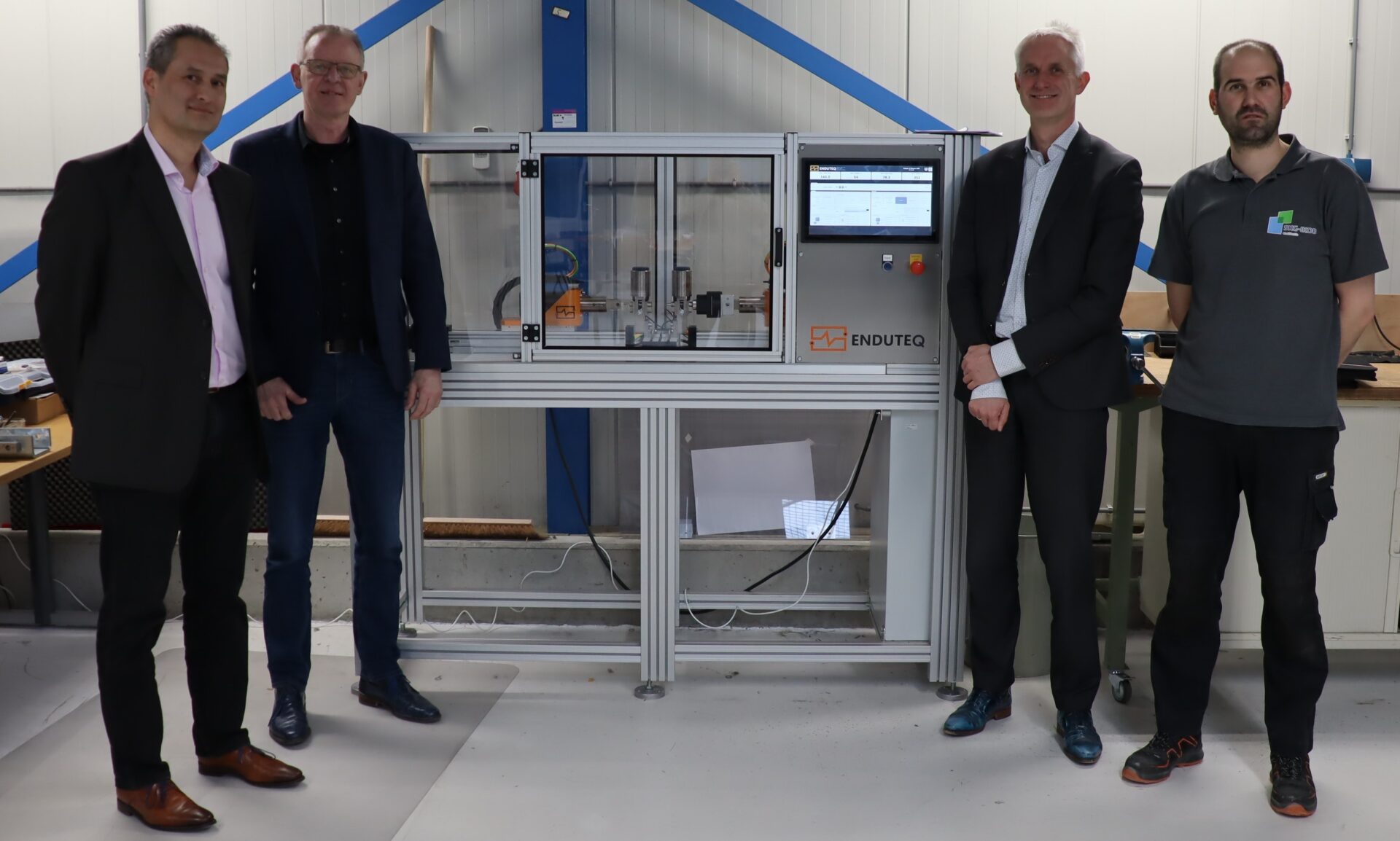

ENDUTEQ provides Cylinder lock tester according to EN1303 to SKG-IKOB

ENDUTEQ has designed and built a freely programmable fully automatic test system for cylinders for locks according to EN1303 for SKG-IKOB from Geldermalsen. With the new setup, SKG-IKOB can have two keys and cylinders undergo an endurance test cycle independently of each other. The new cylinder testing system offers a significantly more efficient method for testing cylinders for locks.

Trigger

The need of producers of products and materials, in order to guarantee the quality of their products, is becoming increasingly important. On the one hand because of (possible) claims from users of their products, further down the chain; on the other hand, to gain more insight into the specific properties and quality of their products.

The newly developed Cylinder Tester not only performs an endurance test in accordance with the standard (EN1303); but is also able to test the material/product really destructively. And can mimic (extreme) operating conditions, in order to help the producer gain more insight into the quality of her product/material. It can also be determined where the limit values of “breaking” the product /material really lie.

The endurance test system replaces an older installation on which only one cylinder could be tested. The new cylinder tester can perform endurance tests on a cylinder from both sides. This allows both the inside and the outside of the cylinder to be tested at the same time. The endurance test is a measure of the life of cylinder and key.

The two test stations mimic the insertion and reversal of the key in the cylinder. The key is screwed onto a holder and turned by a servo motor. Linear units move back and forth during the test to move the key in and out of the cylinder. The system is designed in such a way that it can easily be converted to performing two independent, single tests.

The movement pattern can be set flexibly, and is done by entering various index movements, waiting times and rotations. A complete test can include up to 100,000 cycles. The set movement pattern plus the set parameters can be stored as a recipe in the memory of the controller. There is room for up to 99 recipes. The test system can perform up to twelve cycles per minute, depending on the pattern.

Construction

The cylinder tester consists of a machine frame, two key insertion and rotation stations, two universal cylinder lock clamping housings and a control box.

The cylinder housing is mounted on a mounting block, where the position of the cylinder lock housing is adjustable both vertically and horizontally. The house is equipped with a weight to press the lock according to the standard.

Technical implementation

In order to achieve the desired positioning accuracy, all drives are equipped with servo motors. The key insertion stations are equipped with a linear unit, driven by a servo motor via a spindle. This allows a stroke of 300 mm for the horizontal movement of the key. A servo motor takes care of the rotation of the key. A universal coupling element is mounted on the output shaft for this purpose.

During the execution of the test, the absorbed current of the servo motors is logged; the movement is heavier or lighter. This provides insight into the wear of the key and cylinder.

SKG-IKOB is the Dutch certification body for the construction and real estate sector.The institute provides a total package in the field of quality by testing and certifying designs (certificates), products, processes, services and management systems. Testing cylinder locks is only one part of that.